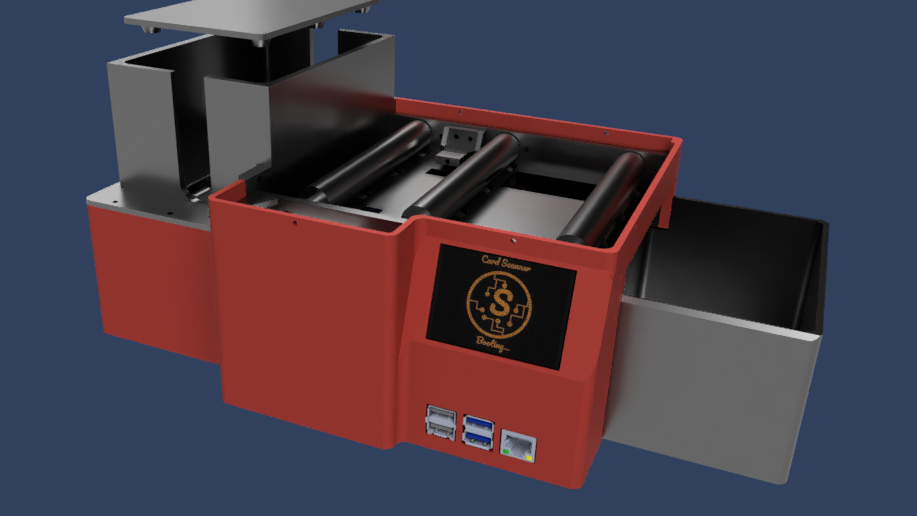

In today’s fast-paced world, efficiency and accuracy are paramount, especially when it comes to data processing. Imagine a device that seamlessly integrates multiple technologies to automate a tedious process, saving time and reducing errors. That’s precisely what I achieved with our latest mechatronics project, leveraging the power of Raspberry Pi, custom PCBs, 3D printing, computer vision, and motor control to create a cutting-edge solution.

This project aimed to streamline the processing of cards containing important information. These cards needed to be scanned, their surface scratched off to reveal a hidden code, and the text extracted and saved to a spreadsheet. Traditionally, this process was labor-intensive and prone to errors. I set out to revolutionize it using advanced mechatronics techniques.

The Components:

- Raspberry Pi: Serving as the brain of the system, the Raspberry Pi provided the computing power and connectivity required to control the entire process.

- Custom PCB: Designed specifically for this project, the custom PCB facilitated precise control over the motors and sensors, ensuring smooth operation.

- 3D Printed Enclosure: Housing all the components securely, the 3D printed enclosure provided durability and protection while maintaining a sleek and compact design.

- Computer Vision for OCR: Leveraging computer vision algorithms, this system could accurately recognize and extract text from the cards, eliminating the need for manual data entry.

- Motor and Positioning Control: Precise motor control allowed me to move the cards through the system with precision, ensuring accurate scratching and scanning.

How It Works:

- Card Input: The device accepts cards from a hopper, automatically feeding them into the system.

- Surface Scratching: A specialized mechanism scratches off the material covering the code on the card, exposing the text underneath.

- OCR and Text Extraction: Using computer vision algorithms, the device captures and processes the text on the card, extracting relevant information.

- Data Storage: The extracted text is saved to a spreadsheet or database, ensuring easy access and organization of the information.

- Card Ejection: Once processed, the card is pushed out of the system, making room for the next one in line.

User Interface:

The entire system is controlled via a TFT touchscreen connected to the Raspberry Pi. This intuitive interface allows users to monitor the process, input commands, and access the extracted data effortlessly.

Conclusion:

This mechatronics project exemplifies the power of innovation and interdisciplinary collaboration. By combining hardware, software, and mechanical design principles, I created a solution that significantly enhances efficiency and accuracy in data processing tasks.

Stay tuned for more exciting projects as we continue to push the boundaries of mechatronics and engineering excellence.